Commercial Electro Plating provides zinc rack and barrel plating services which apply the highest quality durable finishes to your steel, brass, and copper parts. Zinc plating is a proven process used to combat corrosion and rust while also providing an attractive finish. Our processing lines are designed to deliver consistent results in both low and high volume production runs.

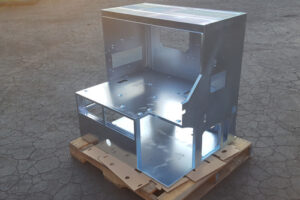

Our zinc rack lines offer capacities to 156″L x 30″W x 50″T while our zinc barrels measure 18″ in diameter and 36″ long, giving us the ability to handle both large and small parts with ease. Post-plate operations include application of a variety of finishes, such as clear or gold RoHs compliant finishes to yellow trivalent chromium, as well as traditional black and gold hexavalent chromates. We also have a post chromate operation, Ultraseal, which is a topcoat sealant that adds to corrosion protection to the part.

Commercial Plating can Zinc Plate to ASTM B633, QQ-Z-325B, and ASTM F1941 for fasteners.

CEP can also POST BAKE your plated parts for Relief of Hydrogen Embrittlement per ASTM B850. Examples of parts that may require this process are springs, bolts, screws, nuts, and or any other parts that may require baking after electroplating. Metals are porous and minor amounts of hydrogen can be trapped in the pores of the part during the plating process. This hydrogen needs to be released so premature failure does not happen under load. The material type will determine how long the bake needs to be as well as how hot the parts will need to be baked.

To learn more about all our capabilities, see the table below, or contact us directly.