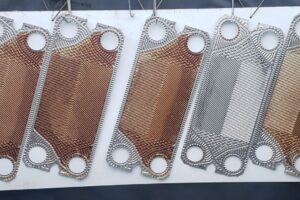

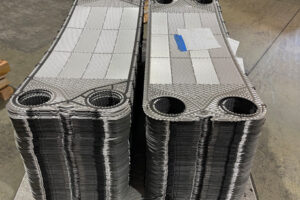

Heat Exchanger Plate Cleaning is a new process that CEP has implemented in 2022. We clean the plates as much as possible using a combination of a dip process with cleaning chemicals and pressure washing. Heat exchange plate usually made of titanium or stainless steel come to us soiled from whatever they might have been heating/cooling. Multiple industries including food, Ag, automotive, and industrial manufacturing all have various liquids that need to be heated or cooled using a heat exchanger. We are capable of cleaning nearly all types of soiled plates including animal fats, hydraulic fluids, fruit and vegetable debris, and many other chemicals that may need to be removed from these plates. Process capabilities 90″L x 46″W x 47″H.

Heat Exchanger Plate Cleaning Services

The cleaning line is primarily used for cleaning soiled heat exchanger plate made from stainless steel or titanium. The cleaning process can remove dirt grease oil food residue as well as many other surface contaminants.

HEAT EXCHANGER PLATE CLEANING GALLERY

- Metal Substrate

-

Stainless Steel / Titanium

- Service Characteristics

-

Removal of soils from surface of heat plates

- Equipment used

-

Racks / hoist

- Post operation

-

Plate Cleaning

- Testing capabilities

-

Cleaning solution concentration

- Tank Size

-

W48” x D47” x L95”

- Part weight

-

up to 1000 lbs

- Additional Services

-

Packing / Delivery

- Production Volume

-

Prototype to large scale

- Lead time

-

2/3 days , rush available

- Specification

-

None

- Industry focus

-

heat exchange refurbishing

- File Type

-

PDF