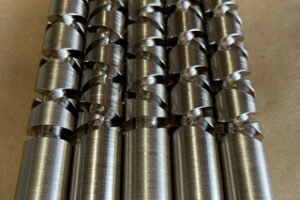

Electroless Nickel Plating is a plating process that deposits Nickel-Phosphorus alloy without the use of external electrical current like traditional electrolytic nickel baths. The Electroless Nickel bath plates uniformly across the surface of the part. This is a huge benefit VS electrolytic plating baths for multiple reasons. A common problem with electrolytic plating baths is the “dog bone effect” or “edge build up”. Since Electroless Nickel plates uniformly across the surface of the part, tight toleranced parts, threaded products, and or mating parts that have very critical tolerances can be controlled to .0001 min up to .003 or more without “edge build up”!! Electroless Nickel also has great lubricity properties, as well as good wear resistance due to the fact that “AS PLATED” Mid Phos Electroless Nickel provides 45 to 51 Rockwell hardness and if you heat treat post plating you can increase the hardness of the nickel to a 64 to 71 Rockwell.

CEP offers a MID PHOSPHORUS ELECTROLESS NICKEL that is ROHS, ELV, and WEE compliant.

We service many different industries including Water Sanitation, Dairy, Ag, Medical, Aerospace, Power Transmission / Distribution, and Petrol Chemical Industries.

CEP has both barrel and rack application with 1 ton hoist capabilities for heavy parts.